Saving money and increasing capacity with the Itensify test units

“We test working pressures of up to 4,000 bar. There are all kinds of safety regulations for that, which you have to pay due attention to. No hose goes out the door without first passing the test bench,” Martien says. “We were faced with a choice: upgrade our old test unit or invest in new machines. After all: when countless high-pressure tests are carried out every day, it is important that the test bench is safe and up to date. But what do you do when your current test unit is dated and in need of an upgrade? Will you then just renew the test bench’s software and hardware? Of course, it would still be a heavily used unit. The amount of money involved was such that we wondered whether that was wise.”

Why Itensify was a logical choice.

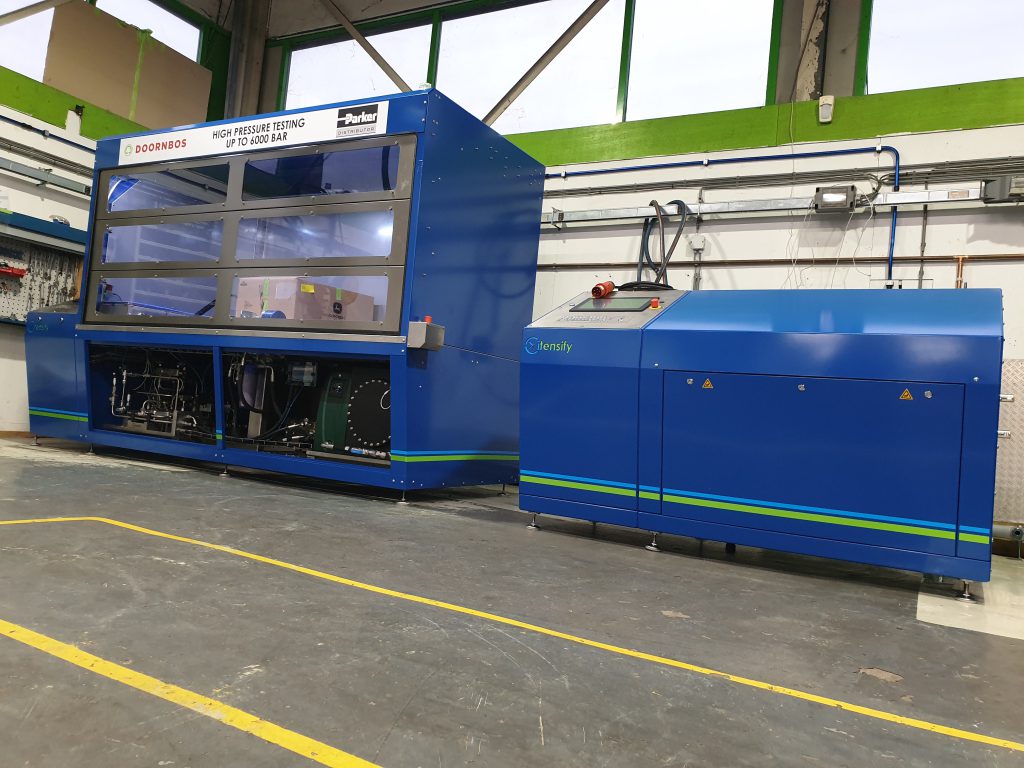

“The market of pressure testing machines is not huge, so you basically know all the parties. Itensify was recommended to us by several parties. To work together only because of this is not immediately a done deal. There was quite a process preceding this, during which we also asked another party. Because we were still facing an additional challenge, we gave the parties additional food for thought. Hermann Egges and Theo de Groot of Itensify anticipated this well, but above all practically. We finally settled on two new test units: the HSP Pro-E-drive, with a spacious integrated test chamber and the WPE Workshop, with reuse of the existing test chamber.”

What exactly were those challenges?

“Not only new hoses, but also the used hoses have to be tested and inspected annually. It happens that the used hoses are contaminated. This regularly led to malfunctions at our previous test unit. We asked Itensify to help us think of a solution to (re)test without failures. They did an analysis of our testing process. This led us to the decision to purchase a unit with a test capacity of up to 6000 bar with a spacious integrated test room for our new hoses. In addition, we wanted to be able to connect hoses with a test pressure of up to 4000 bar to the existing test room, and a rinsing function was added. Itensify’s units thus meet all our requirements”,

“Energy consumption is a lot lower”

What are the advantages of the new Itensify units?

“Our previous unit was air-powered, so the energy consumption was very high. We contrasted the cost of these air-powered units with Itensify’s electric-powered units. The Itensify E-drive units have a big advantage here. The energy consumption of the Itensify unit is significantly lower. In addition, these units are much quieter and cleaner. Itensify guarantees a low maintenance interval, which comes from the design of the electrically driven test solutions. In addition, any failures can often already be solved remotely, by logging in to the machine a fault diagnosis can easily be done. So far, we have found that the wear parts of the Itensify units, are less vulnerable as the units we had before.” Martien continues: “One of the other decisive reasons for making the switch to Itensify is the link to our ERP system. Orders, customer and test data are now all predefined. This makes for a simplified testing process, leading to fewer errors. In addition, Itensify transferred the database of our old test unit to the new one. This allows us to recall data and certificates for up to six years when recertifying. Previously, this all had to be manually retyped to eventually turn it into a new test certificate. Because of this efficiency gain, the operator can now operate two units simultaneously. This has provided a great step forward in increasing our testing capacity.”

“On a Tuesday morning the machines were delivered and on Thursday evening they were running”

How is the cooperation with Itensify going?

“The contact with Itensify is pleasant and approachable. The staff are committed, know what they are talking about and give good advice. The machines were delivered on Tuesday morning and they were running on Thursday evening. The operators were trained to work with the new machines and within a few days we were operational. The rush, cost us about one week of production, which is a very good achievement considering the project size. Most importantly, we always strive for a high level of quality and the Itensify test units are an important part of that!”

Want to know more about Doornbos Equipment? Check out their website!

![]()